C2 PROJECT

C2 Photo Album

album:Christmas 2019

The Porthmadog down distant signal at first light.

One of the steam valve handles, showing traces of its original red paint.

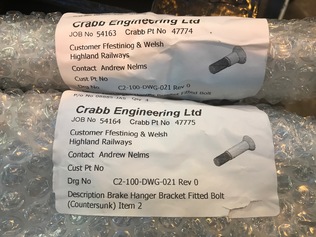

The fitted bolts we bought for the cylinders and motion brackets came beautifully packaged and labelled, complete with an accurate 3D image of what was inside each bundle.

Erle hard at work on the lubricators.

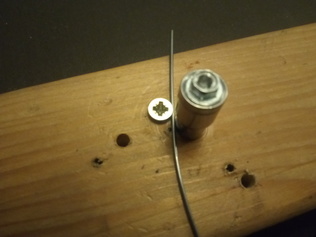

Stages in making new springs for the lubricator ratchets: 1

Stages in making new springs for the lubricator ratchets: 2

Stages in making new springs for the lubricator ratchets: 3

Stages in making new springs for the lubricator ratchets: 4

Stages in making new springs for the lubricator ratchets: 5

A lubricator set up for testing the pumps

Sight glass fitted with the improved design of packer plate and gaskets

Handle components newly painted

Three lubricators in an advanced state of overhaul

Components of the third lubricator now cleaned and painted.

Daves 1 and 2 with Andrew working on reaming holes for fitted bolts.

Daves 1 and 2 with Andrew working on reaming holes for fitted bolts.

New volunteer Matt removes flash from a valve handle.

A selection of steam valves, all of which have been dismantled, cleaned, lubricated and reassembled.

The annual 'Cold Turkey' celebration, held at Llangollen for the first time this year.

Dusk at Llangollen after a very enjoyable day.

Steam valve handles, cleaned up and primed.

More steam valve handles looking a bit brighter with a coat of red paint.

The motion bracket bolts, all now fitted in reamed holes and painted.

Steam valves for the clacks and shut-offs.

Steam valves for the main manifold.

With the motion brackets and brake hanger brackets fitted, attention turned to fitting the cylinders for the final time.

The cavity behind each cylinder was filled with lagging.

Packer plate for fitting between the cylinder and frame. This corrects the slight misalignment and contains the cladding.

Andrew and Olly bolting up the cylinders.

Reaming cylinder fixing holes, much more easily accessible on the carriage inspection pit.

Reaming cylinder fixing holes, much more easily accessible on the carriage inspection pit.

Final views of the locomotive at the end of the Christmas C2 working party. The motion brackets have been painted in grey undercoat in preparation for the application of red paint. - Andrew Nelms 5th Jan 2020

Final views of the locomotive at the end of the Christmas C2 working party. The motion brackets have been painted in grey undercoat in preparation for the application of red paint. - Andrew Nelms 5th Jan 2020